What are industrial heating systems?

Industrial heating systems are essential for various manufacturing processes, providing controlled heat for operations like material processing, drying, and chemical reactions. With our electric heating elements and way of working – advancements in energy efficiency, automation, and sustainability – we are transforming the industry.

Why industrial heating matters

- Enhances production efficiency

- Ensures product quality and consistency

- Supports compliance with industry regulations

- Reduces energy consumption and operational costs

Types of industrial heating systems for industry projects

Industrial heating systems can be broadly classified into direct and indirect heating systems and are powered by electricity, gas, oil, or alternative energy sources. Backer Wilson focuses only on electric and alternative heating methods.

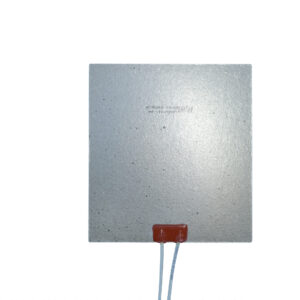

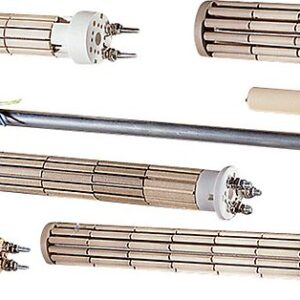

Electric heating systems

Electric heating is growing in popularity due to its precision and eco-friendliness. Key types include:

- Resistance heaters: Convert electrical energy into heat, commonly used in ovens and kilns.

- Induction heaters: Use electromagnetic fields to heat metal parts, ideal for metalworking and forging.

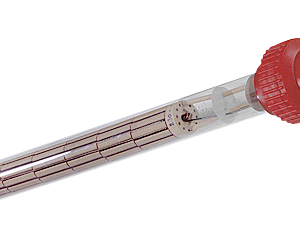

- Infrared heaters: Emit radiation to heat surfaces, widely used in coating and drying applications.

Best for industries requiring precision heating and energy efficiency. Common in food processing, chemical, and heavy manufacturing industries.

Steam and hot water boilers

Boiler systems are widely used for heating and power generation.

- Steam boilers: Provide high-temperature heat for chemical processing, refineries, and power plants.

- Hot water boilers: Used for central heating and moderate industrial processes.

Best for applications requiring large-scale heat distribution.

Thermal fluid heating systems

These systems use heat transfer fluids like oil instead of water or steam.

- High-temperature capability without high pressure

- More energy-efficient than traditional boilers

- Used in plastics, pharmaceuticals, and textile industries

Ideal for processes requiring precise temperature control.

Renewable & hybrid heating systems

With a push for sustainability, many industries are adopting hybrid and renewable-based heating solutions, such as:

- Biomass heating: Uses organic materials like wood pellets for heat generation.

- Solar thermal systems: Harness solar energy for industrial processes.

- Heat pumps: Recover waste heat to improve efficiency.

Eco-friendly solutions reducing carbon footprint and energy costs.

How to choose the right industrial heating system

1. Consider your industry & application

Different industries require specific heating solutions:

- Metalworking & manufacturing: Induction or resistance heating for precision.

- Food processing: Steam boilers for cooking and sterilization.

- Chemical industry: Thermal fluid heaters for controlled temperature processes.

2. Evaluate energy efficiency & cost

Look for systems with high thermal efficiency and low operating costs. Upfront costs might be higher for advanced systems, but energy savings over time justify the investment.

3. Check environmental compliance

Ensure the system meets local emissions regulations and consider low-carbon alternatives to future-proof operations.

4. Factor in maintenance & lifespan

Choose systems with low maintenance requirements and long service life to reduce downtime and costs.

Future-proof your industrial heating system

Investing in the right industrial heating system ensures operational efficiency, cost savings, and environmental sustainability. The shift toward smart, energy-efficient, and low-emission heating technologies will continue shaping the industry.

Looking to upgrade your industrial heating system? Contact our experts today for tailored recommendations!