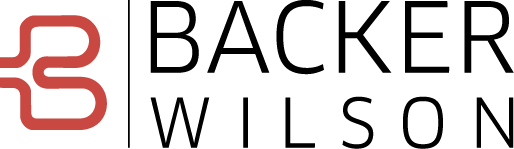

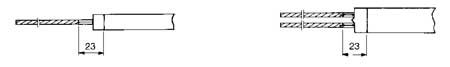

Tubular element with dia. 8.5 mm and 14 mm can be fitted with fins, stripped vertically on the element. The fins increase the radiating area and reduce the surface temperature on the element without sacrificing heat transfer. Alternatively, higher surface temperatures can be used to decrease the size of the element. The heating element can be manufactured with a connection at one end or two.

Benefits – Finned elements

Heating element with dia. 8.5 mm and 14 mm can be fitted with fins to increase their heat dissipation surfaces. Fins are available in steel for soldering or in zinc-aluminum alloy for press-fitting to tubular elements of 8.5 mm diameter. Fins in zinc-aluminum alloy are available for press-fitting to 14 mm dia. elements.

- Reduced surface temperature

- Increased radiation area

- Compact design of application possible

Examples of applications | Tubular air heating elements for everyday and everywhere

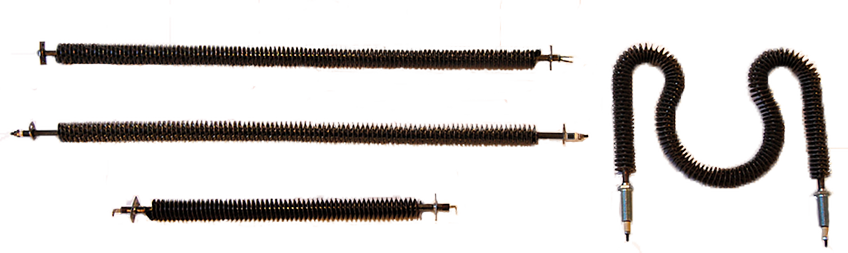

The Backer tubular heating element is the most frequent alternative for liquid heating. We are specialists a large number of production techniques, providing you with a wide selection of element types. An optimal heating solution for a specific application is determined by the user environment and operating temperature. Backer supply elements with an operating temperature ranging up as much as 900°C.

- Radiators

- Convectors

- Anti-freeze devices

- Power resistors

- IR-radiators

- Heat curtains

- Sterilizers

- Ovens

- Body side heaters for trains etc.

- Frost protection

Technical data

|

Material |

Steel – Grade D |

|

Dimension |

Tubular dia: 8.5 or 14 mm |

|

Assembly |

Nipples, fixing plate etc. per customer spec. |

|

Connection |

M4, cables, flat pin per customer spec. |

|

Voltage |

Max 600V |

|

Safety |

Meet requirements per EN 60335-1 |

|

Others |

Can be soldered for higher performance |

|

Type |

Band |

Ext. dia. |

Elementdia. |

Pitch |

Bending radius (mm) |

|

280 S |

SS 1160 |

28 |

8,5 |

6 |

25 |

|

280 R |

AISI 304 |

28 |

8,5 |

6 |

25 |

|

340 S |

SS 1160 |

34 |

14 |

9 |

30 |

|

340 R |

AISI 304 |

34 |

14 |

9 |

30 |

Tubular element of certain diameters can be fitted with fins, stripped vertically on the element. The fins increase the radiating area and reduce the surface temperature on the element without loosing heat transfer. Alternatively higher surface temperature can be used to decrease the size of the element. The heating element can be manufactured with connection at one or two ends.

Fixing and connection devices

Cost savings can often be made if elements are fitted with connection and attachment devices during manufacturing. We offer several standard solutions. We can also supply special flanges and alternative methods of fixing made completely according to our clients’ specifications. When selecting connection and fixing devices it is often important to bear in mind the size of the series. Do you want to know more about our fixing and connection devices? Please contact us.

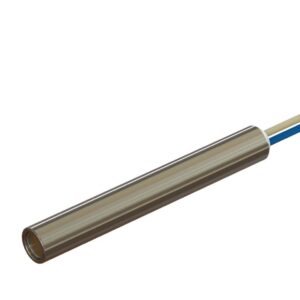

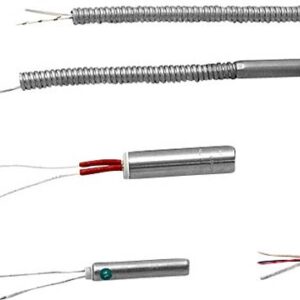

Types of cables and wiring

The heating elements can be supplied with connecting wiring which is normally spot welded to the terminal pins. Uninsulated as well as insulated wiring is available. Uninsulated wiring can be fitted with insulating tubing. The joint between the wiring and the terminal pin can also be fitted with insulating tubing if required.

The most commonly used types:

|

Wiring material |

Insulation material |

Max. operating temp. |

|

Copper |

– |

180°C |

|

Copper |

Silicone |

180°C |

|

Copper |

Fiberglass/silicone |

180°C |

|

Nickel |

– |

400°C |

|

Nickel |

Ceramic bushings |

400°C |

|

Nickel |

Fiber glass/silicone |

200°C |