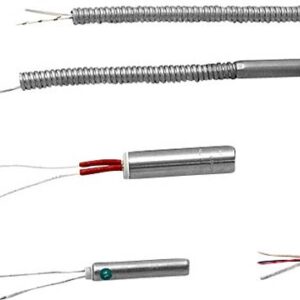

Nozzle elements – Essential in the plastics-, casting, and rubber industries

Band heaters are used for contact heating in machines and for heating of molds and tools, mainly in the plastics-, casting – and rubber industries. Band heaters, made of micanite or ceramics covered with metal sheeting, are used for contact heating in injection machines/extruders and for heating of containers, tanks, etc. Nozzle elements for extruders are always in stock. Nozzle elements are produced with high precision and with high surface loading capacity to meet the high demands for quick and safe heating. Nozzle elements for plastic extruders we kept in stock. During the manufacturing process the element is subjected to very high pressure to attain high insulation resistance, good heat transmission without internal voids in the element and a very smooth surface for optimal and uniform heat transmission from the total surface of the element. The element is tightly sealed to keep molten plastic, oil or gas, for example, from leaking in.

Nozzle elements ideal for extremely corrosive environments | Technical data

Ring and band heaters are used where there is a need for indirect heating or constant heating of a fluid in a container or tank, liquid plastic in extruders, in injection machines and also when drying glue in fixtures and molds.

|

Material |

Brass sheath |

|

|

Connection |

|

|

|

Voltage |

230 V |

|

|

Surface loading |

4.5 W/cm² |

|

|

Tensional stability |

2 kW |

Standard design – For optimal and uniform heat transmission

|

Diameter |

|

Power W |

Voltage |

|

|

25-60 mm |

25×20 – 60×60 |

80-505 |

230 |

|

|

60-100 mm |

65×20-100×60 mm |

180-840 |

230 |

Special design

Stainless steel sheath for very corrosive environments, such as for PVC injection molding, which also allows a higher temperatures and surface loading 7W/cm2. Thermal sensor type J for temperature regulation. Alternative connections see above.

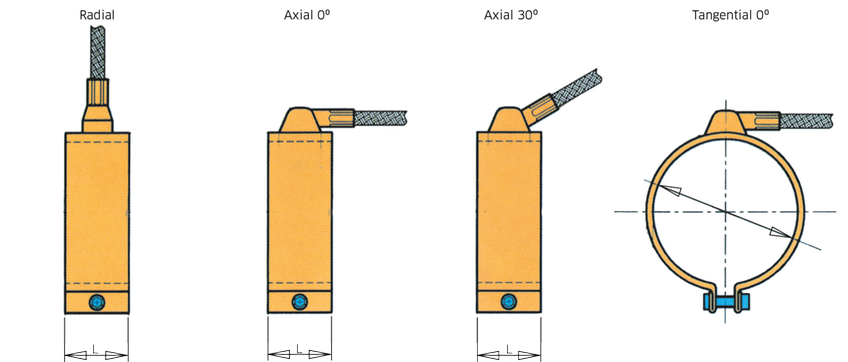

Assembly instruction

Socket head cap wrench 4 mm is used. It is very important that the nozzle element is thightly assembled to avoid any internal voids between elements and injenction molder nozzles, for example. After initial heating, the nozzle element must be re-tensioned. Avoid bending the connection cable close to the element. Avoid bending the connection cable close to the element. Remaining plastic material at element surface can be removed by heating to melting point. Avoid impact to the element and take good care when removing plastic.

Technical data

|

Connections |

Connection box |

|

|

Design |

Ceramics with sheet metal casing |

|

|

Surface load |

Max 8W/cm² (at max 300°C) |

|

|

Max operating temperature |

|

- Type of heating: Contact heating

- Dimension: As agreed with customer

- Fields of application:

- Extruders

- Containers

- Tanks

- Moulds

- Tools, etc

- Connection:

- Connection box

- Nickel wire

- Cabinet inlet

- Flat pin connectors

- Design:

- Ceramics with casing of plate

- Micanite with casing of plate

- According customer specification

- Others:

- Max surface load: 8 W/cm² (at max 300°C)

- Max operating temperature 700°C (at max 4.5W/

cm²)

Example applications | Band heaters for machines, molds and tools

- Contact heating

- Extruders

- Containers

- Molds

- Tools

- Tanks