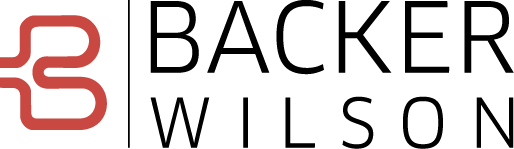

Cast-in elements – Heating shields

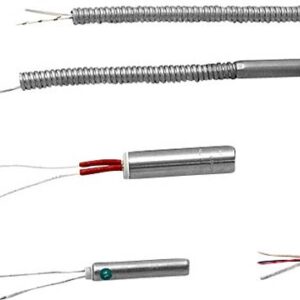

Cast-in elements can be used for indirect heating of liquids for instance in tanks, for example, but also for direct heating in oil pre-heaters. Backer tubular heating elements can be cast in an aluminum alloy such as silumin. Embedment of a tubular heating elements increases the heat-emitting surface and enables the element to be adapted to different applications. Backer tubular heating elements can be produced cast-in in an aluminium alloy. The cast-in

technique offers advantages such as influencing the temperature regulation of a large mass, uniform heat emission and low operating temperatures thanks to the fact that surface enlargement can be integrated with the element.

Technical data | Cast-in elements for direct & indirect heating

- Type of heating:

- Indirect liquid heating

- Contact heating

- Convection/air heating

- Material: Aluminium alloys

- SS-EN-46000

- SS-EN 44300

- Brass

- Dimension:

- Maximum 500 x 500 mm, in certain cases even

bigger

- Maximum 500 x 500 mm, in certain cases even

- Fields of application:

- Heating plates

- Oil heating

- Motor heaters

- Tool heaters

- Frying tables

- Assembly: Fixing to the object

- Connection: M4, flat pin, spot welded cable, round pin

- Type:

- One or two wattage ratings/element

- According customer specification

- Standard range

- Can be manufactured with UL, VDE approval

|

Material |

|

|

|

Dimension |

approx. 500×500 mm, in certain cases even larger |

|

|

Assembly |

Attachment in object |

|

|

Connections |

M4, flat pin, spot welded cable, round pin |

|

|

Designs |

One or two wattage ratings/element |

Example applications – Suitable for several different applications

- Motor heaters

- Electric water heaters

- Resistance

- Air heating

- Oil heating

- Heating plates

- Heating shields