Immersion heaters

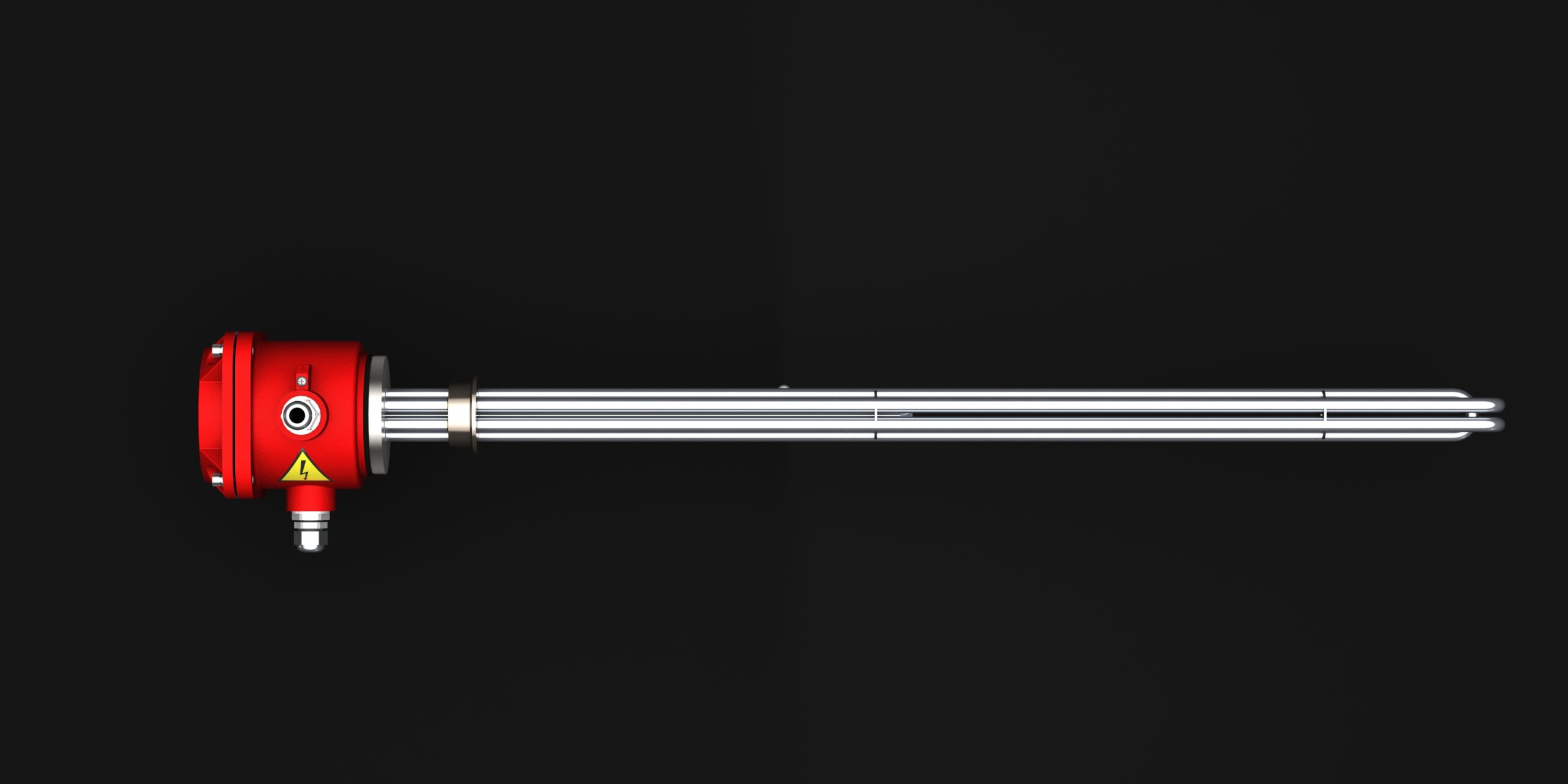

An immersion heater is composed of three main components: the heating elements (tubular elements), a screw plug, and a connection box. The heating elements are attached to the plug through soldering or TIG welding. This design results in a compact heater that ensures optimal heat transfer to the medium being heated.

Immersion heaters

Immersion heaters are used for heating water, oil, air, and a wide variety of other liquids and gases. Depending on the application, they can be supplied with or without integrated temperature control and safety thermostats housed within the connection box. Both the control and high-temperature safety thermostats are available as single-pole or three-pole devices. These heaters can be manufactured in virtually any power rating and supply voltage. We offer a comprehensive range of standard immersion heaters to meet the most common industrial needs. Heaters are available with stainless steel or bronze screw plugs in various standard sizes, including 1″, 1.25″, 1.5″, 2″, 2.5″, and 3″. Heating elements are typically made from Incoloy, nickel-plated copper, Inconel, or stainless steel.

Removable immersion heaters

Removable immersion heaters are designed for heating liquids in open tanks with low or fluctuating fluid levels—common in applications such as degreasing baths or surface treatment processes. These heaters can be installed either vertically (on the wall) or horizontally (on the tank bottom), depending on process requirements and spatial constraints. For use in shallow tanks, the heaters consist of tubular elements (Ø 6.5 – 8.5 – 10 – 16 mm) with an appropriate unheated length. Electrical connections are routed through a stainless-steel tube that leads to the terminal box, allowing for flexible configurations such as 1-phase or 3-phase (star or delta) connections. In addition to tubular elements, removable immersion heaters can also be made with glass, porcelain, stainless steel, or titanium tubes containing ceramic heating elements. These versions are ideal for heating aggressive or corrosive liquids. For highly corrosive environments, Backer Wilson offers Teflon-coated immersion heaters specifically designed to withstand extreme chemical exposure.

Customized solutions

In addition to our standard product range, we offer extensive customization options—including immersion heaters with integrated temperature control, multiple-element configurations, and more. Whatever your requirements, we’re happy to help you find the right solution. Our immersion heaters are also available in explosion-proof designs and UL/CSA-certified versions, ensuring compliance with the highest safety standards.

What are screw-in elements used for?

Screw-in elements are designed primarily for heating water and oil but can be used to heat almost any liquid or gaseous substance. At Backer Wilson, we’re happy to help you determine the right screw-in elements for your specific application. We also offer custom-made screw-in elements when required.

Customizable screw-in elements

Our screw-in elements can be supplied with or without temperature control and/or safety thermostats housed in the connection box. Both the control thermostat and the maximum temperature safety thermostat are available in single-pole and three-pole versions. Additionally, our screw-in elements can be manufactured to almost any desired power rating and voltage. We offer a standard range suitable for the most common applications. The elements come with stainless steel or brass screw-in glands in various standard sizes, including 1″, 1.25″, 1.5″, 2″, 2.5″, and 3″. Standard materials for the heating elements include Incoloy, nickel-plated copper, Inconel, and stainless steel.

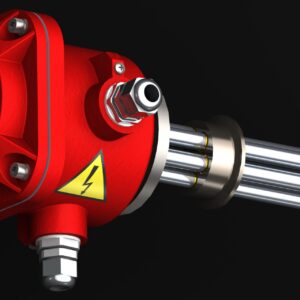

Explosion-proof screw-in elements

Backer Wilson screw-in elements are also available in explosion-proof designs and/or with UL certification. Additionally, we offer a comprehensive range of connection housings—including round, oval, rectangular shapes made from steel or plastic—making our screw-in elements suitable for virtually any application.