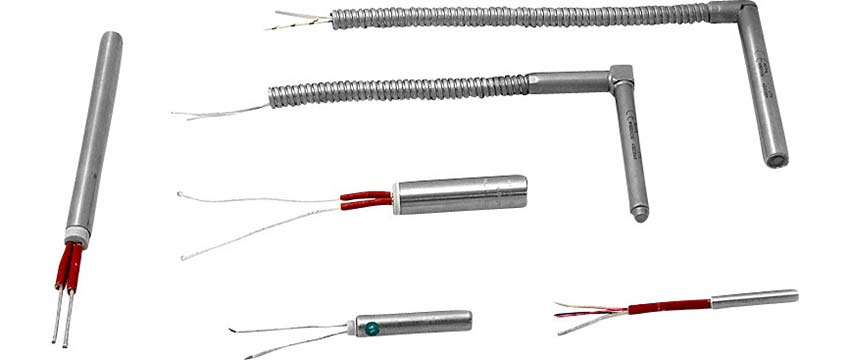

Cartridge heaters, high power elements | Quick and high power for tool heating

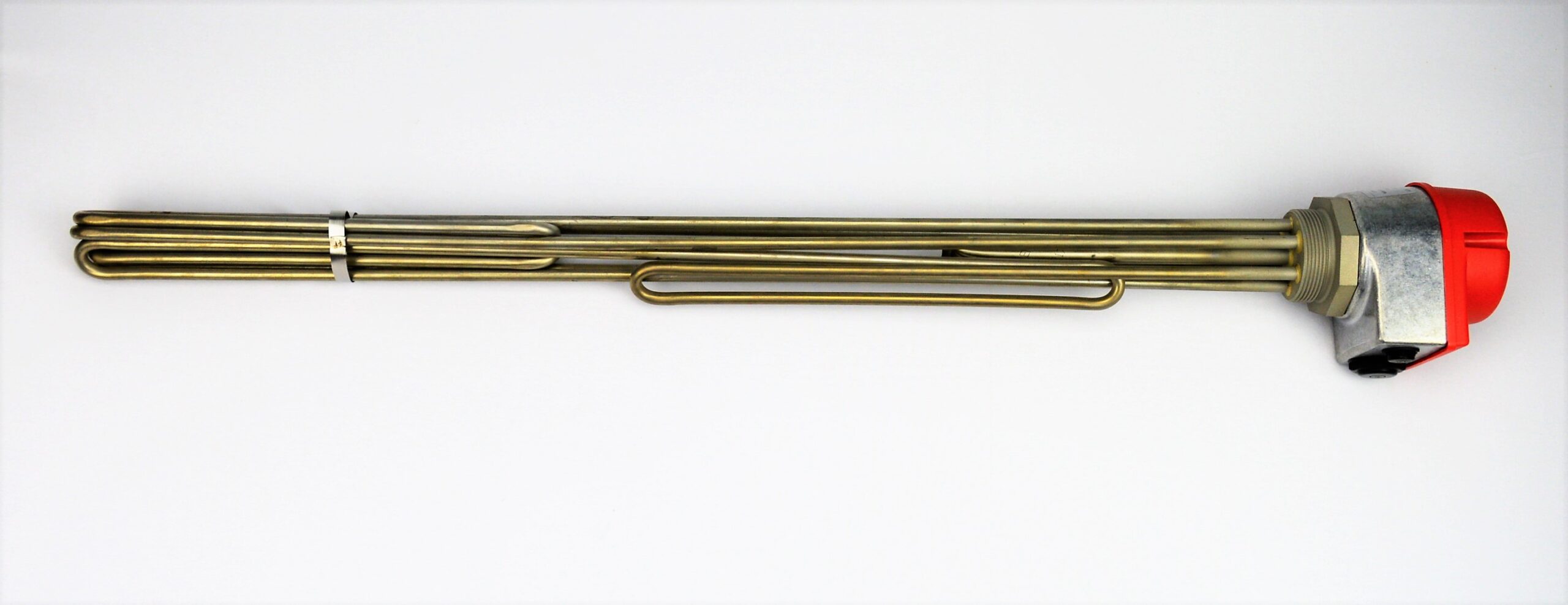

Cartridge heaters, or high power elements, can supply very high power to a specific area and are mainly used to heat tools. Thanks to the design, the heat is quickly distributed over the entire surface of the element and the elements comply with the high demands for impact resistance to impact and vibrations. This high performance cartridge heater is designed to meet all needs of heating and dimensions. This heater eliminates the need of small tolerances of the hole diameter as well as an individual adaptation, since it expands to fill the drill hole when power is put on. The recommended drill hole diameter is 0.18 mm larger than the nominal diameter of the cartridge heater shown below.

Technical specifications

- Type of heating: Tools with hole matching H7

- Material: Stainless steel AISI 321

- Dimension: Ø 6.5, 8, 10, 12.5, 16, 20 mm

- Fields of application:

- Tool heating for e.g. plastic- rubber-,

wood- and paper industry - Equipment for medical technical and

laboratory industry - Braking systems

- Foundries

- Tool heating for e.g. plastic- rubber-,

- Connection:

- 250 mm glass fibre armoured nickel wire

- Helical protective hose, zincified steel strip

- Wave hose (gas- and liquid tight)

- Armoured hose, zincified

- Right angle casing

- Types

- Standard range

- Acc. to customer specification

- Others:

- We also have cartridge heaters with water proof seeling; build in thermo element; and Ex- classed

|

Material |

Stainless steel AISI 321/EN 1.4541 |

|

Dimension |

Ø 6.5 , 8, 10, 12.5, 16, 20 mm Inactive section approximately 10 mm at the connection end and approximately 5 mm at the other end. |

|

Connection |

250 mm fiberglass-reinforced nickel wire Helical protective hose, zincified steel strip Wave hose (gas- and liquid tight) Reinforced, hose, zincified Right angle casing |

|

Others |

Broached holes are required. Tolerance H7 (Swedish standard). If a surface load greater that 20W/cm2 is required, individual adjustment is necessary. |

Benefits

- Easy to mount and dismount

- Lower demands of tolerence on the hole diam.

- Can replace trad. cartridge heater in cases when the drill hole

is too big

Applications

- Tool heating

- Plastic industry

- Packaging industry

- Flight industry